EASY INVENTORY PERFORMANCE BOOST — DECIDE STOCK STATUS AND SAFETY STOCK TOGETHER

By Terry Harris, Managing Partner, Chicago Consulting

The Stock Status (Stock or No-stock) decision and the Safety Stock decision you make have profound impact on how your inventory performs–the Fill it provides and the Capital it requires. In the vast majority of inventory systems the Stock Status decision of each item is made first and the Safety Stock decision second. Additionally these decisions are almost always made on different bases, with different criteria.

For example, a Stock Status decision might be to “stock any item that was ordered at least three times in the last year.” A Safety Stock decision might be “two-weeks worth.” These decisions are independent of each other and applied separately–at different times.

There’s a better way. Make these decisions together and on the same basis. Your inventory will perform better–it will provide higher Fill with less Capital.

It’s easy to see why. These two decisions have exactly the same effect. Stocking another item does the same as increasing the Safety Stock of a Stock item–it increases the Fill the inventory provides and the Capital it requires. Accordingly these decisions should be made together and under the same standards.

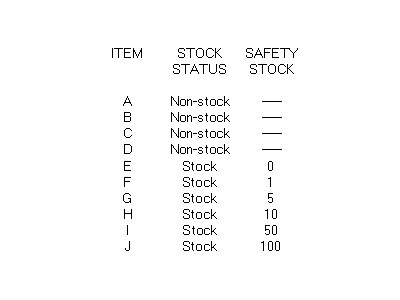

Here’s an example:

Increasing the Fill this inventory provides can be done in two general ways and many specific ways. The Stock Status of any item A through D can be changed to Stock, causing the Fill and the Capital required of the whole inventory to increase, or the Safety Stock of any item E through J can be increased. The effect is the same–higher Fill and higher Capital. To be sure the precise numerical Fill and Capital increases depend on the specific item, but the directional effect is exactly the same.

More specifically in this situation you should consider two options – 1) making any of items A through D a Stock item coupled with a Safety Stock of zero and 2) increasing the Safety Stocks of any item E through J by one. Then pick the option that provides the best benefit. To restrict the consideration to just one of these alternatives degrades inventory performance. To make the comparison of these two options with different criteria also degrades performance.

Of course, the same principal applies if you wish to get cash out of your inventory and are willing to bear the related Fill reduction. Make the Stock Status and the Safety Stock decisions together and you’ll get more cash out for lower decline in Fill.

Check out your own processes. Do you, like most, first decide what items to stock then their Safety Stocks? Organizations that separate these choices or make them on different bases lower their inventory performance, causing it to operate at diminished Fill and require more investment.

Did you think there was nothing new under the “inventory management sun”? Here’s a simple change, you’re likely not taking advantage of, that will boost your inventory performance.