DYNAMIC SLOTTING WITH “EXPECTED TIME TO PICK

Don’t Zone Your Warehouse, ETP it

By Terry Harris, Managing Partner, Chicago Consulting

Zone Approach

Traditional slotting techniques use a Zone structure. The warehouse is divided into a group of Zones, typically a handful of them. Then each position in a particular Zone is viewed the same as all the other positions in that Zone. This is a coarse representation of the real world. Large warehouses have thousands of positions. Traditional Zone techniques employ just tens of Zones, perhaps fewer. The Zone approach forces

hundreds of positions to be exactly the same as each other.

Of course the main idea is to put “fast movers up front.” However, “up front” is not a well defined concept, particularly with Zones containing hundreds of positions. Because vertical travel is slower than horizontal travel, higher positions are not as valuable as lower ones slightly further into an aisle, for example.

Also “fast movers” are normally established from another group structure—typically ABC or velocity-based classes. That structure has all the same rough granularity as the Zone structure—perhaps thousands of items get shoehorned into just a few ABC classes.

Better Way

Expected Time to Pick (ETP) is a better way. In this approach the “Accessibility” of every position in the warehouse is determined specifically for that position—the lowest possible level of detail.

Accessible positions make up the high value “real estate” of your warehouse. Accessibility is linked to the time needed to travel to a position—the longer it takes the less accessible the position. Positions prioritized on travel time are automatically prioritized on Accessibility. This prioritization, rather than the time itself, is all that’s needed for ETP.

So with ETP “up front” is crystal clear—it means “short time to travel to and from” and can be measured in a straight-forward unambiguous way.

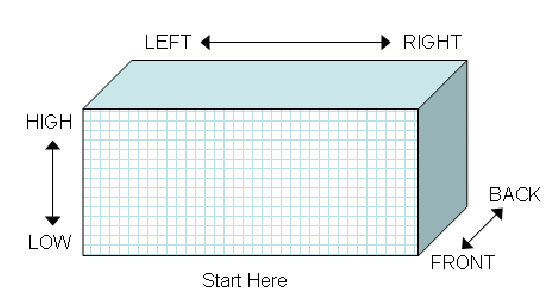

Imagine a warehouse of like positions as a cube with Left-Right, Front-Back and High-Low dimensions.

For this example, assume that the front face is completely accessible and that the other faces are unable to be accessed—as if they were flush against a wall. Assume also that aisles run front to back and that pickers start at the middle of the front face at ground level. Then it’s easy to specify the Accessibility of every storage position.

Ground level positions on the front face near the start have the highest Accessibility. High positions in the back at the left and right extremes are the least accessible. Those not very deep into an aisle would be slightly less accessible than their corresponding positions on the front face. Ground level positions are more accessible than ones directly above them. And so on.

Zone structures are groupings of smaller abutting blocks that fit inside the larger cube. Yet positions in two far apart Zones can have the same Accessibility. For example, a position well down an aisle, at ground level and on the right can be just as accessible as one slightly elevated, near the front and far to the left. This reality is awkward to represent with a Zone structure. With ETP it’s simple, quantitative and accurate.

Having determined the Accessibility of warehouse positions we need only put material away properly to take advantage of ETP.

Where to Put a Receipt

ETP is the amount of time until it is expected, or forecast, that the item will be traveled to and picked. If this time is short you want to store the item in an accessible position, obviously. If it’s long you want to store it in an inaccessible position because you won’t need to go there to pick it soon and, more importantly, it will not be in the way of getting at faster moving items. It won’t take up valuable real estate. Receipts with the largest ETPs should be put in the “back 40”—deep in the aisle, left or right and high.

Arithmetically ETP is the on-hand quantity minus the amount back ordered all divided by the forecast:

ETP = (On-hand – Back Order) / Forecast

ETP is calculated at the time the item is to be put away.

As an option the on-hand in the ETP calculation can include the amount to be put away. In this case the ETP will be the expected time to pick what’s on-hand plus the receipt that’s to be put away. This has advantages in some situations.

Mapping Function

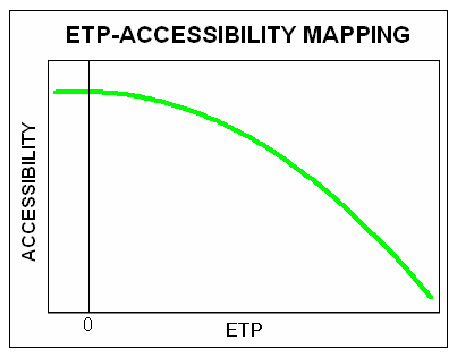

Once ETP is calculated the decision of where to put the receipt is determined from a “Mapping Function.” This function translates ETP into Accessibility and, so, a specific position with that Accessibility.

The Mapping Function might look like this

Note the function assigns low ETP items to highly accessible positions and vice versa. The exact shape of this function should be determined experientially. It will depend on how full your warehouse is, how fast your inventory turns and the amount of congestion you wish to tolerate.

Congestion

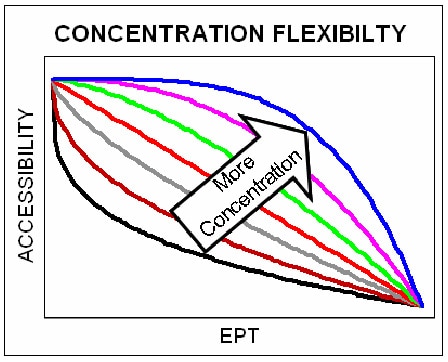

Congestion, for example, is avoided by lowering the concentration of fast movers stored in high accessible positions. This would correspond to a flatter Mapping Function-closer to a straight line, perhaps even concave rather than convex.

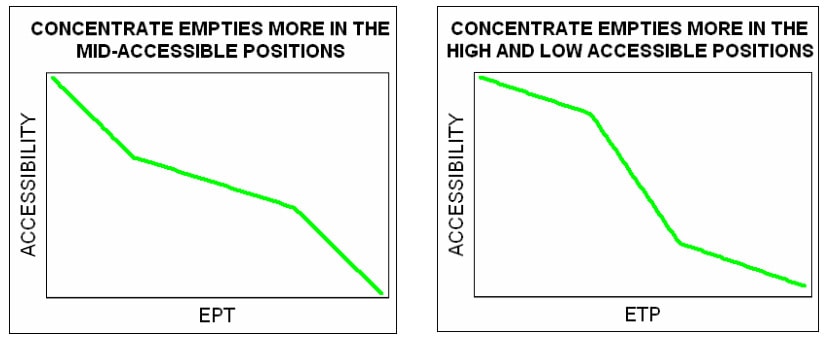

Not all congestion need be avoided. When it occurs in high value real estate pick times are short. Just how much congestion to allow along with the productivity it fosters is likely a matter of experience and judgment. This trade-off can be controlled with the shape of the Mapping Function illustrated like this

Somewhere between concave and convex there’s the right Mapping Function for your warehouse.

That a warehouse can have the same high Accessibility in widely dispersed positions scattered throughout it relieves congestion automatically. For this and other reasons it’s possible, under ETP, that high value real estate can be utilized to the maximum extent possible with no congestion at all.

Cross-Docking

ETP makes cross-docking a breeze; “back order purging” too. Items that should be cross-docked are those with a negative or zero ETP; their back order amount is equal to or greater than their on-hand. Therefore negative and zero ETP items can be placed in a cross-dock position with the ETP approach. Just assign the cross-dock position as the most accessible in the warehouse; which, of course, it should be anyway.

Housekeeping

As time goes by on-hand amounts, back order quantities and forecasts change. What was put in an inaccessible position may later benefit from being promoted to a more accessible one. ETP supports “housekeeping” – this routine re-arrangement of items.

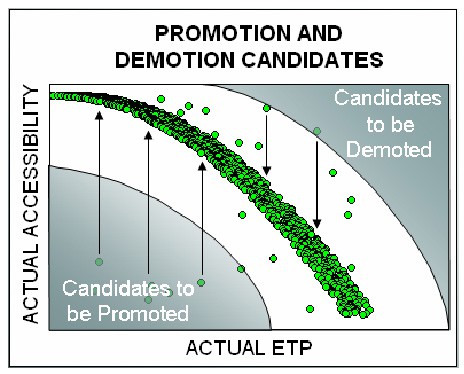

To identify positions to be promoted and demoted just plot the current actual ETP and Accessibility of the warehouse like this

High priority items to be promoted or demoted are ones that are far from the Mapping Function, in the South-West and North-East corners respectively.

Housekeeping directions can be interleaved in the picking and put-away functions of the WMS. So, for example, when a picker has put an item away, she can be directed to a nearby location for a housekeeping move.

Other Refinements

Beyond congestion, cross-docking and housekeeping ETP has the flexibility to accommodate other special situations:

• With multiple position picks on a picking tour, such as building a case-picked pallet, ETP is even more effective because its close proximity advantage applies over all those multiple picks. In this situation the ETP calculation might include the amount received and account for the number of times the position would be

visited—“bin trips,” for example

• With full pallet picking it is likely that Accessibility should include the original put-away move too. This would account for the receiving dock location and represent the total put-away plus pick time

• A variety of storage formats such as rack positions with different dimensions or bulk and off-site storage can be accommodated with refinements to the Mapping Function

• Products stored in sectors according to their physical characteristics—cases of automotive oil filters and fenders, for example—are accommodated by having a separate Mapping Function for each sector

• Multiple slotting, in which a position holds more than one item, is arranged by Mapping Function refinements

• Warehouses must have empty positions in which to put receipts. Some refer to this as the “85% Rule.” However many empty positions are needed, the question arises as to where should empties be concentrated. This can be done with the shape of the Mapping Function. Illustrated here are two Mapping Functions that orchestrate empty concentration in different ways

Easy Implementation

You don’t have to massively rearrange the warehouse to take advantage of ETP. Just start putting receipts in the right place and the benefits will begin to accrue automatically.

The speed at which your warehouse becomes efficient depends on your inventory turns. Since you should be receiving faster movers this time ought to be short—shorter than the

time for one turn, for example.

To free up more high accessible positions, start a modest housekeeping activity—move items way above the Mapping Function (shown above) to the back 40.

From a systems perspective, and once your warehouse positions are prioritized on Accessibility, the put-away logic is really simple. Just calculate ETP and find the position with the corresponding Accessibility determined from the Mapping Function. The on-hand, back order and forecast, which should be readily available, are all that are needed for the ETP calculation. It even works for items with a zero forecast!

Benefits

The ETP approach values your warehouse real estate specifically and in detail—it quantifies “up front.” Then it keeps accessible positions both occupied with the right items and turning over fast. Whenever they are emptied, they are rapidly filled up again with fast movers which are again picked quickly. What could be more sensible?

Conversely ETP keeps slow movers out of the way. Pickers aren’t required to constantly pass by old dusty positions on their way to get what customers ordered!

ETP’s advantages include

- Pick times are decreased, productivity is increased

- It incorporates and details the “Golden Zone” and all similar ideas

- Congestion can be managed directly and easily—allow some or avoid it all together—with the shape of the Mapping Function

- ETP achieves many of the advantages of batch picking and may make it unnecessary

- By EPT’s recognition of common Accessibility that may be widely dispersed throughout the warehouse, congestion is diminished and might be eliminated completely

- It’s the quantitative way to prioritize routine housekeeping promotions and demotions

- Using the item-level forecast eliminates the coarse granularity of velocity-based classes

- Positions are not forced into a handful of arbitrarily established Zones and treated like all the others in their Zone

- It maps the warehouse to the lowest possible level of detail

- No Zones—no maintenance. They don’t shrink, expand or move around; they don’t exist

Don’t zone your warehouse, ETP it!

About Chicago Consulting

Chicago Consulting designs and engineers supply chains for manufacturers, distributors and retailers. It fits together components such as procurement, inbound logistics, warehouse networks, inventory deployment, transportation, operations within warehouses and the systems that assist these functions. The firm is 25 years old, with headquarters in Chicago and offices in Shanghai and Johannesburg. The firm’s website is www.chicago-consulting.com and phone number is (312) 346-5080