Managing Inventory in the Downturn

Chicago Consulting

The signs of the coming downturn are widespread. UPS volume slows 10%, Amazon lays off warehouse workers and stalls its expansion. The list goes on. Inventories expand in downturns. Inventory Turns drop. How can we cope? Here are simple practical steps to stem the routine inventory expansion in downturns.

JUMP THE FORECAST

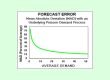

Almost all forecasts are a mixtures of recent and older history, recent and older past unit sales. For example, in the exponential smoothing technique with a smoothing constant of 15%, recent history is weighted by 15% and older history by 85%. This means that forecast sales will dramatically lag aggressive downturns. The forecast will overstate actual sales and will be slow to catch up.

The way to deal with this is to intervene in the traditional formulaic forecasting process and “manually” insert a one-time decrease(s) in the forecast. Reset the formula’s output based on your human intuition. If you believe the downturn is coming make your forecast benefit from your knowledge.

SHORTEN LEAD-TIMES

As your economic activity slows so will that of your suppliers. Their Lead-times to supply you will shorten. Manufacturing Lead-times will shorten too, your whole supply chain tightens. If you forecast Lead-times, get a leg-up by a one-time adjustment. If you have fixed Lead-times rethink them and adjust them to what you believe is right.

DECREASE SAFETY STOCKS

Safety Stocks should be a function of forecast and Lead-time variability. As these two decrease, their variability will decrease as well. Find how your Safety Stocks are dependent on Lead-time and forecast variability and adjust them downward.

CUT REPLENISHMENT QUANTITIES

Replenishment Quantities are generally dependent on inbound economics—buy a container load, a truckload, buy a pallet’s worth, a case and so on. If they are tied together, Replenishment Quantities should decrease as forecasts diminish. If not, you should review the Replenishment Quantities and their respective inbound economics. Understand their connection and establish fresh Replenishment Quantities that fit your new situation.

PROMOTE EXCESSES

Every inventory subject to random demand has Items in excess. If your overall inventory turns three times a year you will have Items that turn less than once per year. These are the result of past forecast overestimates. They are unavoidable. The way to manage these Items is to [promote them, typically based on price. Promote them singly or upsell orders for other Items. These slow-moving Items choke off the rest of your inventory velocity as they collect dust on your warehouse shelves.

PLACE BALANCED ORDERS

Companies that order multiple Items from a given supplier should place Balanced Orders. These are orders in which the quantities of all the Items on it will bring your resulting inventories in balance, so that each Item will reach its respective Reorder Point at the same time next time around.

CONTRACT THE NETWORK

The benefit of multiple regional warehouses is to provide shorter Lead-times to customers and, possibly, decrease freight expense. This comes at the expense of more warehousing costs. In downturns you may be willing to take the Lead-time hit on a few customers to save warehousing expenses. Contracted regional networks have the added advantage of diminishing inventory by making fewer slow movers which are inherently hard to forecast.

REBALANCE INVENTORY

Multiple regional warehouse networks have Items in excess in one please and short in another. These are rebalancing candidates. Find these imbalances and make a one-time shipment from one warehouse to another. Use the backhaul in the same way, just with different Item. Buy from yourself.

Inflexible formulas and fixed inventory management structures are typically designed for the steady state. When you know you are in a downturn or anticipate one, don’t sidestep your intuition and experience. Get a head-start on the downturn right away.