NEGATIVE SAFETY STOCKS

By Terry Harris, Managing Partner, Chicago Consulting

There is a need for Negative Safety Stocks in a Reorder Point inventory system. In such systems it is usual to have some items designated as “Stock” items and others designated as “Non-stock.” The former are planned to always have some On-hand – a replenishment is received just when the On-hand is planned to reach its Safety Stock. The latter is planned to never have any On-hand – it’s not replenished, it’s ordered when a customer orders it but not for inventory replenishment.

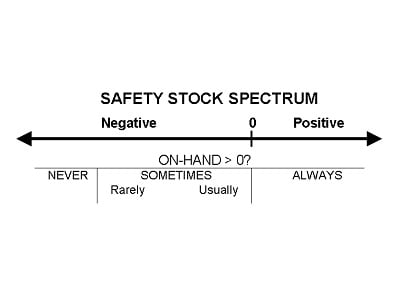

This structure (Stock or Non-stock) anticipates an On-hand that is either never greater than zero or always greater than zero – a clear and wide dichotomy! Why not fill in the gap with sometimes greater than zero? Negative Safety Stocks create the capability for a positive (non-zero) On-hand “sometimes” and a zero On-hand at “other” times. An item with a Negative Safety Stock would have less capital and Fill contribution than if it were a Stock item and more than if it were a Non-stock item.

That there is a role for Negative safety Stocks is easily understood. In most inventory systems there is a relatively broad spectrum of Velocity—from slow to fast movers. The Stock/No-stock decision is frequently made on this spectrum. Other dimensions, such as item level Cost, are also used from time-to-time. Without Negative Safety Stocks items are either “always” or “never.” Common sense suggests that a more nuanced approach, one with more options, one that allowed for “sometimes,” will allow the inventory to perform better – more Fill for less Capital.

Negative values for Safety Stocks will work perfectly well in current Reorder Point systems with no modification. In such systems a Re-order Point is calculated as the Safety Stock plus the usage during the Lead-time. Then a replenishment is scheduled when the On-hand reaches the Reorder Point. It is perfectly acceptable to have a Reorder Point calculated from a negative Safety Stock. The formula, Reorder Point = Safety Stock + usage during the Lead-time, works regardless of the value of the Safety Stock.

A Negative Safety Stock can be used to make the Stock/No-stock decision. If the Safety Stock is set to –usage during the Lead-time – 1, then the Reorder Point will be -1, the On hand (or, really, the Available to Promise) will never reach it and a replenishment order will never be placed – exactly what should happen with a Non-stock item.

Finally having a procedure that constructs both negative, zero and positive Safety Stocks can then be used to make the Stock/Non-stock and the Safety Stock decision all at the same time and, most importantly, on the same basis. No need to separate these decisions. After all deciding to not stock an item has exactly the same effect as deciding to lessen another item’s Safety Stock – it diminishes both the capital invested in the inventory and the Fill it provides customers. These decisions should be made on the same basis.